Bidirectional Control of DC Motor using transistor based H-Bridge with single input

22:02 | Posted in BASIC ELECTRONICS, Electronics Circuits, H-Bridge, H-Bridge with single input, How Stuff Works? | Read More »

RMS Voltage Control Circuit with MOC3021 and BT136

Triac is a power electronic component that conducts in both directions when triggered through gate. Figure below shows a generic working of triac.As it can be seen that at time t1, angle of sinusoid is 45' which means that if we triggered triac at this angle i-e at 45', only shaded blue area will pass through the triac and hence through the load. Observe that shaded blue are has RMS Voltage less than the pure sinusoid. This is the basic principle by which RMS Voltage control is accomplished. Firing needs a small pulse at gate that can be give through microcontroller also. Similarly at firing angle 90' (firing angle is an angle with reference zero crossing at which the triac is triggered using gate pulse) , only red part of sinusoid will pass through the triac giving us the RMS 110V for 220V.

Triac is a power electronic component that conducts in both directions when triggered through gate. Figure below shows a generic working of triac.As it can be seen that at time t1, angle of sinusoid is 45' which means that if we triggered triac at this angle i-e at 45', only shaded blue area will pass through the triac and hence through the load. Observe that shaded blue are has RMS Voltage less than the pure sinusoid. This is the basic principle by which RMS Voltage control is accomplished. Firing needs a small pulse at gate that can be give through microcontroller also. Similarly at firing angle 90' (firing angle is an angle with reference zero crossing at which the triac is triggered using gate pulse) , only red part of sinusoid will pass through the triac giving us the RMS 110V for 220V.21:16 | Posted in Electronics Circuits, Electronics Projects, Fan Speed Control, Light Dimmer, RMS voltage control | Read More »

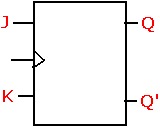

JK Flip Flop - Combination of SR and T Flip Flop

- Behaves as RS Latch / Flip Flop (here J=S and K=R) for all input values except for J=K=1

- For J=K=1, (this is state has to be avoided in SR), JK Flip Flop toggles the value similar to T-Flip Flop.

12:46 | Posted in BASIC ELECTRONICS, Digital Electronics, JK Flip Flop | Read More »

T Flip-Flop using D Flip-Flop

The feedback connections make the input signal D equal the value of Q or Q' controlled by an input signal D. At every positive edge when T=0, D=Q and this state will remain same. When T=1 at positive edge clock, D=Q' and will remain unchanged. The overall operation is that: it retains it present state at T=0 and toggles it when T=1.

The feedback connections make the input signal D equal the value of Q or Q' controlled by an input signal D. At every positive edge when T=0, D=Q and this state will remain same. When T=1 at positive edge clock, D=Q' and will remain unchanged. The overall operation is that: it retains it present state at T=0 and toggles it when T=1.12:34 | Posted in BASIC ELECTRONICS, Digital Electronics, T-Flip Flop using D Flip-Flop | Read More »

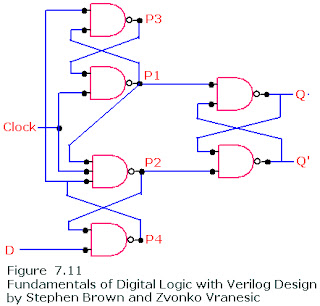

Positive Edge D Flip Flop using 6 NAND gates only

- When clock=0, P1 and P2 are high (i-e P1=P2=1). keeping the values of Q and Q' intact.

- At the same time P4= complement of D and P3=D.

- Now when clock=1 (at positive edge), the values of P3 (equal D) and P4 (complement of D) passes through P1 and P2.

- Now P1=D' and P2=D which means Q=D and Q'=D'

- When D=0, P2=0 which will keep the value of P4=1 regardless of the value of D

- When D=1, P2 and P3 remains high regardless of the value of D.

12:12 | Posted in BASIC ELECTRONICS, Digital Electronics, Positive Edge Triggered Flip-Flop using NAND Gates | Read More »

Working of Master Slave Negative Edge D Flip-Flop

As seen in the figure, Master-Slave D Flip-flop consists of two D Latches. Master changes its state when clock=1 while the latter changes its state when clock=0. When the clock is high the masters track the value of D but since the slave is in inactive state, Qs also remains unchanged, Now when the clock signal goes low, the master goes to inactive state and the slave which is now in active state it tracks the value of Qm. While clock=0, Qm does not change its value. Thus we can say that only once during the clock cycle the slave can undergo change in its value. This gives us a generic idea of working of flip-flops.

As seen in the figure, Master-Slave D Flip-flop consists of two D Latches. Master changes its state when clock=1 while the latter changes its state when clock=0. When the clock is high the masters track the value of D but since the slave is in inactive state, Qs also remains unchanged, Now when the clock signal goes low, the master goes to inactive state and the slave which is now in active state it tracks the value of Qm. While clock=0, Qm does not change its value. Thus we can say that only once during the clock cycle the slave can undergo change in its value. This gives us a generic idea of working of flip-flops.11:00 | Posted in BASIC ELECTRONICS, Digital Electronics, Master Salve Negative Edge Flip-Flop | Read More »

Gated SR Latch using NAND Gates

12:29 | Posted in BASIC ELECTRONICS, Digital Electronics, Gated RS Latch | Read More »

Gated SR Latch using NOR Gates

This latch is active high, that is when clock signal goes high the Gates SR Latch behaves as a normal SR Latch. And when the clock signal goes low, whatever the logic at inputs maybe, the output will remain the same unless and until the clock signal goes high again.

This latch is active high, that is when clock signal goes high the Gates SR Latch behaves as a normal SR Latch. And when the clock signal goes low, whatever the logic at inputs maybe, the output will remain the same unless and until the clock signal goes high again. The characteristic table is given below. Many authors use the term characteristic table rather than truth table - this is because truth table is usually linked with the circuits whose output(s) solely depends upon the input(s) only which is not the case here. The table below is same as that of SR Latch except that it is controlled using clock signal.

The characteristic table is given below. Many authors use the term characteristic table rather than truth table - this is because truth table is usually linked with the circuits whose output(s) solely depends upon the input(s) only which is not the case here. The table below is same as that of SR Latch except that it is controlled using clock signal.12:14 | Posted in BASIC ELECTRONICS, Digital Electronics, Gated RS Latch | Read More »

A Memory Element using NOR Gate - SR Latch

- When Q=0, Q'=1 and when Q=1,Q'=0 under normal conditions

- When R=0 and S=1, the latch is set into "S E T" state i-e Q=1 and Q'=0

- When R=1 and S=0, the latch is set into "R E S E T" state i-e Q=0 and Q'=1

- When both R and S equals low logic, the SR latch holds is previous states

- The last possibility of R=S=1 gives us the illegal (unpredictable|) value. Some authors say that Q=Q'=0 in this state.

09:39 | Posted in BASIC ELECTRONICS, Digital Electronics, SR Latch | Read More »

Block Diagram of Ethernet Based Control of Electric Appliances with Touch Panel Interface

11:19 | Posted in BASIC ELECTRONICS | Read More »

Block Diagram of DC Servo System

13:08 | Posted in BASIC ELECTRONICS, Block Diagrams, How Stuff Works? | Read More »

MATLAB based Project Ideas

Here is list of project ideas based on MATLAB for graduate and post-graduate students:

- Impulse Noise Filter

- Palm-print identification system

- Finger-print identification system (enhancement using filtering)

- Modelling of 3-phase power system (Filtering method)

- Implementation of Motion detection algorithm

- Digital Filter (Bilateral) for image diffusion

- Code Shift Keying Impulse Modulation

- Speaker Recognition in Noisy Environment

- Principal Component Analysis for face recognition

- Designing Antenna using CDMA

- Voice Recognition

- Coding of Stereoscopic Images

- Touch less Finger Print recognition system

- Ultrasound Speckle Image Processing

- Development of Sesmographic system

- Analysis of Volumetric Chest CT Scans

- Bit Error Rate Analysis of OSTBC Transmission

- Text independent speaker verification

- Iris recognition algorithm

- Online Signature verification algorithm

22:23 | Posted in MATLAB, Matlab Simulink | Read More »

Basic Block Diagram of Data Acquisition System (DAS)

- No processing can be done

- More memory needed

- Less readable due to Infinite Readings

12:58 | Posted in BASIC ELECTRONICS | Read More »

Temperature Sensors Comparisons

- Thermistor (Resistive Inverse Non Linear)

- Thermocouple (Nom Linear - High Temperature Ranges)

- RTD (Resistive Linear)

- LM34 / LM35 / LM334 / LM335 (Solid State)

- Diode based Temperature sensor

11:43 | Posted in BASIC ELECTRONICS, How Stuff Works? | Read More »

Theory of 8051/AT89S52 based SMOKE DETECTOR and FIRE ALARM SYSTEM

1. Microcontroller ATMEL 89S52.

2. Temperature sensor LM-35.

3. Smoke sensor TGS-308.

4. 16x2 LCD.

5. Operational amplifier IC LM-324.

6. 12 Volts Buzzer.

7. 6 Volts Relay.

8. Potentiometers 10K.

9. 5 Volts Voltage regulator 7805.

10. BJT C-1383 NPN-type

11. Crystal oscillator 11.0592 Mhz.

12. LED’s.

13. Push button.

14. Capacitors.

15. DB-25 Connector.

16. ISP Programmer.

17. KEIL UVision-2.

18. 9 Volts Adapter.

19. Weiroboard.

20. Wiring and miscellaneous.

More Details see Project Report and Coding

10:25 | Posted in Electronics Projects, Microcontroller | Read More »

8051/AT89S52 based SMOKE DETECTOR and FIRE ALARM SYSTEM

Importance

- Indicate the room in which fire erupted

- Sound the alarm if fire occurs

- False Alarm occurrence should be kept minimum

- The system should be flexible enough to be easily modified in case if new rooms are added to the building

- The system should also provide the flexibility to adjust the temperature and smoke sensitivity levels as per the operating environment

- The system should never be in any ambiguous state. Under normal conditions the system should indicate the state of the room as ‘NORMAL’ in order to avoid any confusion.

HEAT DETECTION CIRCUIT:

- In case if both the bits of a particular room are high (i.e. the smoke and heat levels are above normal conditions), the program sets the pin connected to the buzzer, turning it ON.Simultaneously the LCD displays the room number of the room where fire has erupted.

- In case if one of the bits of a particular room is set (i.e. either the smoke sensor or his operating above normal conditions), the program takes this situation as ambiguous and displays “NORMAL” on the LCD.

- If both the bits are at low logic levels (i.e. both the heat and smoke sensors are operating under normal conditions), the program simply displays “NORMAL” on the LCD and the buzzer also remains OFF.

- The programming approach to display output on the LCD includes character by character transfer of the entire string with an appropriate delay. The LCD is initialized only once and only the top line of the LCD is being used for display purpose.

20:49 | Posted in Electronics Projects, Microcontroller | Read More »